GHL Doser 2.1 Stand Alone, 4 pumps, white, Schuko

€535,00

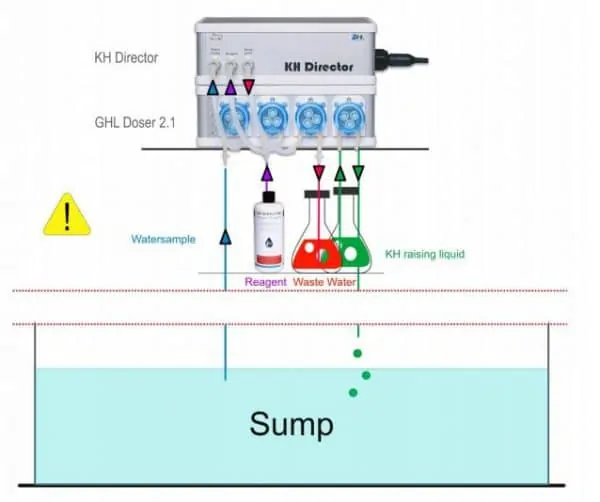

The GHL Doser 2.1 Stand Alone works independently and is therefore NOT a GHL profilux control unit. Can be expanded with SLAVE pumps

Out of stock

GHL Doser 2.1 Stand Alone, 4 pumps dosing pumps

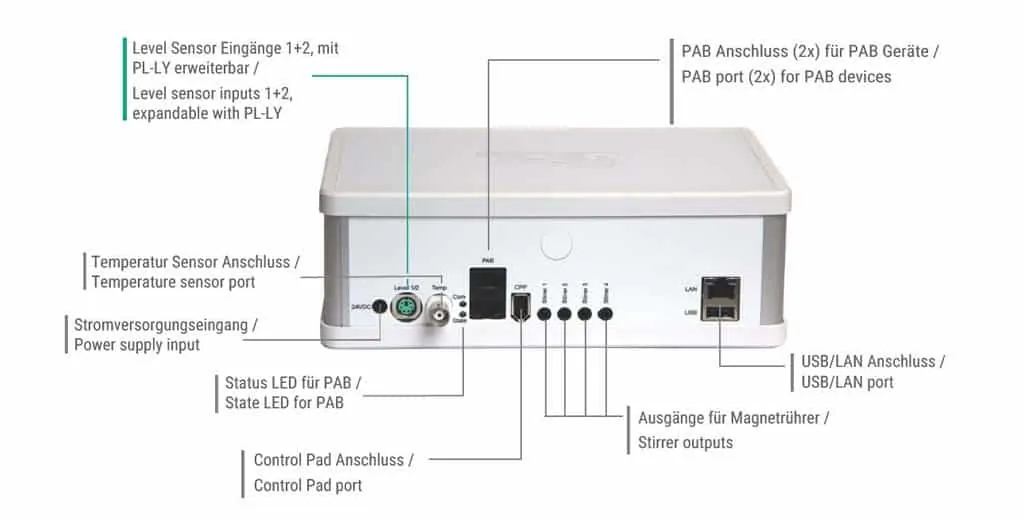

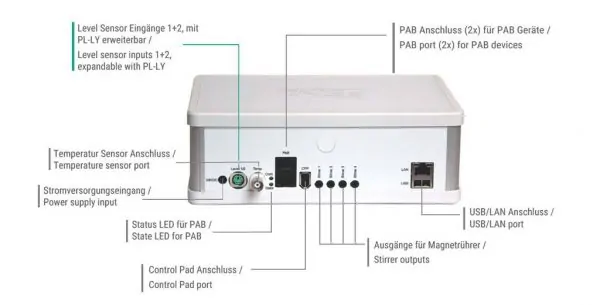

The GHL Doser 2.1 Stand Alone operates independently, meaning it is not a GHL Profilux control unit. You can expand it with SLAVE pumps whenever needed. The 24 V stepper motors ensure precise dosing, even for the smallest flow rates of 0.1 ml. You can connect it via WiFi, LAN, or USB.

This system can be expanded to include a total of 16 pumps:

- Stand Alone + 3 Slave Doser

- ProfiLux Controller + 4 Slave Doser

The ProfiLux Aquatic Bus guarantees reliable and efficient data transfer, even over long distances of up to 100 m (300 ft).

Technical specifications:

- Color: Black

- Dimensions: 220 x 150 x 75 mm (without pumps)

- Variants: 4 pumps

Scope of supply:

- Dosing pump unit Stand Alone (white)

- Power supply unit

You can achieve milliliter precision and automate the dosing of various liquids such as:

- Fertilizers

- Trace elements

- Balling salts

- Lime water

- Liquid supply

Additional features include:

- Integrated evaporated water filling (Auto Top-Off)

- Water exchange of small volumes

- Stainless steel motor shafts (suitable for dosing iodine)

- Chemical resistant tubes (Norprene)

- Manual operation of each individual pump is possible

- Pumps can be installed later

- Individual parts can be replaced (pipes, pump head, motor)

- 24V stepper motors allow micro doses of 0.1 ml

- Up to 150 doses per day

You can easily choose dosing times via the GHL Control Center software. There are two modes available:

- Automatic: Up to 150 individual doses per day that are automatically distributed.

- Individual: A maximum of 8 doses per day can be set individually.

Regarding convention capacity and dosage, the system can adjust from 8 to 45 ml per minute (accurately adjustable to 0.1 ml).

The Dose 2.1 pumps are designed to be largely maintenance-free. For best performance, it is advisable to clean and remove dust and other impurities from the inside of the pumps occasionally. Please note that the pumps must not be lubricated in any way!

Tubes, pumps, and motors are wearing parts, and their lifespan depends on usage frequency, power quantity, and environmental conditions. In case of defects such as insufficient flow, loss of filling power, leakage, or increased operating noise, or if there is any mechanical damage, the wear parts must be replaced. Thanks to the maintenance-friendly design, all wear parts can be easily replaced, and they are available as accessories.

| Weight | 2,0000 kg |

|---|---|

| Show MyParcel options |